Communication Systems

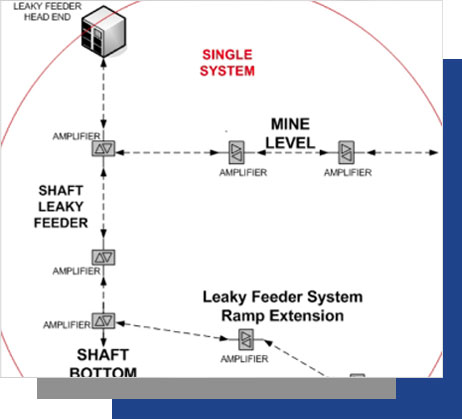

Leaky Feeder Radio Communication

Wireless underground Communication system in mining.

Radio waves travel by line-of-site, making radio communications underground difficult. Leaky feeder solves this problem by forming an antenna that is installed throughout the mine, providing complete mine wide radio communication – now that is new innovations in mining at its best.

O.R.F.I.

Optical to RF Interface (O.R.F.I.) can be easily integrated to any existing Leaky Feeder system and is typically used to redistribute larger systems fed from 1 main source, reducing single point of failure and simplifying fault location.

The wireless underground communication system in mining also lends itself to extend RF coverage to remote areas where leaky feeder surface coverage is limited or does not currently exist. ORFI is not limited to standard leaky feeder installations as it can also be interfaced to existing RF systems in order to extend coverage into building or tunnels.

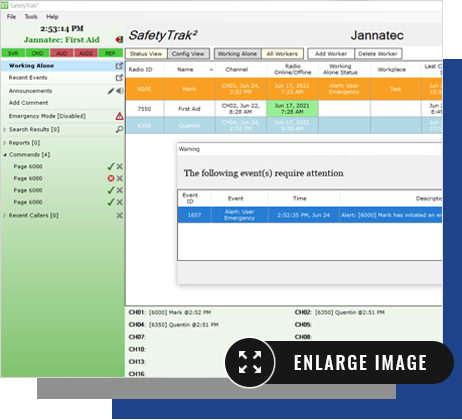

Safety Trak Platform

When installed on a leaky feeder system, Safety Trak can uniquely track each miner every time the two-way radio is used. A number of events can be tracked over a period of time. When miners are working alone, a check-in time can be set (2 hours). If the miner does not check in, Safety Trak will automatically page the miner continuously until check-in occurs. If the miner fails to check in within a set grace period (determined by the mine) a supervisor is dispatched to physically find and check on the miner’s well being. The Safety Trak system can also perform a “Radio Check” or silent handshake to ensure the radio has not failed.

Finally, if the situation is serious, Safety Trak can send a signal to open the microphone and listen to the ambient noise in the miner’s work area for up to one minute or as determined by mine management. The background noise could provide valuable information as to the reason(s) why the miner has failed to check in. Safety Trak can also provide an audible alert (horn or siren) in the event the emergency button is activated. Other features include mine evacuation or notification to report to refuge station. While monitoring miner activity, the Safety Trak System can also record the activity and write the data to a database.